Rapid capabilities testing and modifications

The traditional view of capability design being a long, drawn out and expensive process has been changed with a move towards capability ‘sprints’ and the acceptance of learning and failing fast in order to develop.

Our Mission System design and modification team have developed a rapid prototype and test methodology that allows for:

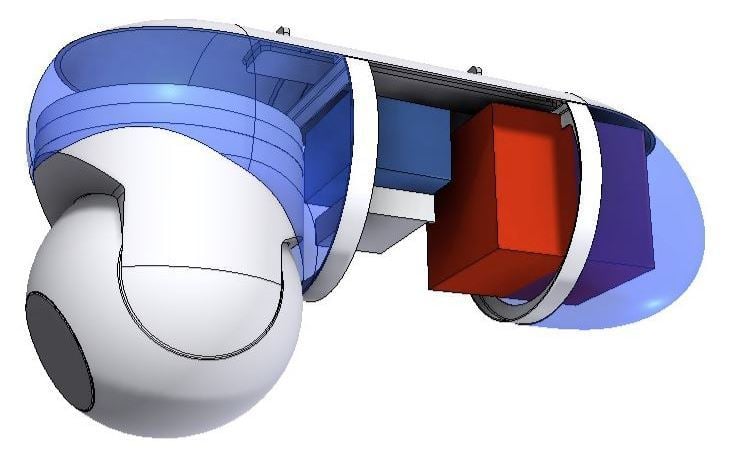

- Trial of upgrades to Comms, ISR, SIGINT and COMMINT technologies

- Performance testing of missile seeker heads & defence systems

- Development and trial of IR shrouds

- Development and trial of mitigating items to overcome sensor / DIRCM drag

- Improvement in platform performance to increase MTOW and mission endurance

- The use of civilian avionics upgrades to reduce cost & increase asset life

A different take on capability testing

Rapid capability testing requires a different, more creative approach. For example a Cessna 172 can be a perfect platform for exploring the capabilities of a new drone senor. A Formula One team’s understanding of the properties of carbon fibre can lead to lower thermal signatures. LiDAR and digital prototyping can deliver millimetre perfect demonstrations of ergonomic consoles. A PA-28 can trial a major avionics upgrade for a battlefield helicopter.

All of these techniques were used to make a difference, at a substantially lower cost than traditional development techniques.

Civil and Military approvals

Our approvals cover design, testing, production and installation on civil and military types. This allows us to operate in both worlds and not be myopic when considering the development path of moving from test to full installation. As an organisation we hold the following approvals:

- BSI Certificate of Registration to ISO 9001:2015 Nº 620796

- UK CAA Part 21J Approval Nº UK.21J.0174

- UK CAA Part 21G Approval Nº UK.21G.2678

- UK CAA Design BCAR A8-21 Approval Nº DAI/9961/15

- UK CAA Production BCAR A8-21 Approval Nº DAI/9961/15

- Military Aviation Authority (MAA) DAOS approval Nº UK.MAA.DAOS.0322

We work frequently with the following national and international authorities:

Mechanical design capability

Modifications and repairs typically require mechanical design. The team are experienced in all aspects from technical survey, initial hand calculations, through detail design development to creation of production drawings and computer aided manufacturing data.

Examples of projects and additional services covered by our Mechanical Team include:

- 3D Scanning

- Adapter Plates

- Antenna Installations

- Anti-Vibration Mounts

- Blanking Plates

- Bulkhead Penetrations

- Chart Holders

- Circuit Breaker Panels

- Detail, Assembly & Installation Drawings

- Doublers (Internal & External)

- Empennage Changes & Repairs

- Equipment Mounts

- Equipment Racks & Trays

- Fairings

- Flooring

- Fuselage Changes & Repairs

- Ground Support Equipment

- Hard Points

- Instrument Panels

- Mission System Consoles

- Mock-Ups

- Monuments & Stowages

- Rapid Prototyping (3D Printing)

- Structural Repairs

- Tie Rods

- Wing Changes & Repairs

Mission systems: Electrical design capability

Modifications and repairs with electrical aspects will involve numerous assessments, such as power distribution, electrical load analysis and electromagnetic compatibility.

Typical projects undertaken by our Electrical Team include:

- Annunciator Panels

- Annunciators

- ARINC Signal Converters

- Avionic Backup Batteries

- Battery Upgrades

- Circuit Breakers

- Communication Ports (RJ45, RS-232)

- Electric Start Systems

- Generators

- Ground Use Batteries

- Instrument Panel Lighting

- Equipment Mounts

- Instrument Panel Plugs

- Inverters

- LED Lighting (Internal & External)

- NVIS Lighting

- Passenger Service Units

- Power Outlets

- Redundant Wiring Removal

- Switch Guards

- Switches

- USB Charging Sockets

- Wiring Diagrams

- Wiring Repairs

Avionic Design

Avionics, (derived from the term “aviation electronics”) makes up a large percentage of our work.

Our Design Team have a wealth of knowledge and experience in all areas of avionic design and integration, from simple instrument replacements to a full glass cockpit upgrade.

Typical projects undertaken by our Mission System Avionics Team include:

- ADS-B In & Out Solutions

- Air Data / Attitude Heading Reference Systems

- Airborne Image Recording Systems (AIRS)

- Angle of Attack Systems (AOA)

- Antennas (All Types)

- Audio Panels & Intercom Systems

- Cockpit Voice & Flight Data Recorders (CVFDR)

- DME, NDB’s & VOR’s

- Downlink Systems

- Electronic Engine Instrumentation

- Electronic Standby Instrument Systems (ESIS)

- Emergency Locator Transmitters (ELT)

- Flight Management Systems (FMS)

- Flight Test Instrumentation (FTI)

- Glass Cockpit Upgrades

- Global Positioning Systems (GPS)

- Inertial Navigation Systems (INS)

- Instrument Landing Systems (ILS)

- Performance Based Navigation (PBN)

- Primary & Multi-Function Flight Displays (PFD & MFD’s)

- Radar Altimeters (RADALT)

- Satellite Communication Systems (SATCOM)

- Terrain Avoidance & Warning System (TAWS)

- Traffic Collison Avoidance Systems (TCAS)

- Transponders (Elementary & Enhanced)

- VHF & UHF Communications

- Weather Radar (WX)

Mission systems. ISR and rear operator equipment

A large percentage of the Mission System’s teams Design & Production projects are Mission Systems focused, our approvals allow us to produce modifications for both military and civilian registered aircraft.

The team excel in providing special mission design solutions for Surveillance, Law Enforcement and Government operators.

Typical projects undertaken by our Missions Systems Team include:

- Augmented Reality Mapping Systems (ARS)

- Cabin Wi-Fi

- Customer Specific Systems

- Digital Audio Communication System (DACS)

- Downlink & Uplink Systems

- Inertial Navigation Systems (INS)

- Light Detection and Ranging (LiDAR)

- Mission Displays & Monitors

- Mission Seating

- NVIS Lighting

- Operator Consoles

- Operator Workstations

- Retractable Camera Installations

- Satellite Communication Systems (SATCOM)

- Software Defined Radio Systems (SDR)

- Specialist Antennas

- Surveillance Role Fits

- TACAN

- Tactical Radios (TETRA)

- Threat Simulation

- VHF & UHF Communications

- Video / Mission Recorders

- Video Management Systems (VMS)

Flight testing and Performance

Our Mission System team possess the ability to carry out Flight Testing under our own approval, commonly referred to as Flight Test Operations Manual (FTOM) approval.

Flight Testing is often required when an aircraft has undergone significant modification which could have an affect on the flight characteristics of the aircraft, such as installation of an external store.

Prior to the approval of the modification the aircraft may have to be flown under Approved Flight Test Conditions (AFC) to gather compliance data needed to approve the modification.

We possess the in-house capability to perform the following:

- Approval for Flight Test Categories 2 & 4

- Approval of Flight Test Conditions (AFC)

- Major Changes & STC’s

- Validations of Minor Changes, Repairs & STC’s

- Experienced in working with the vast majority of the world’s NAA’s

- Experienced in both Civil & Military certification

Modification performance testing

To ensure our Mission System modifications and parts meet both our customer and regulatory requirements, we regularly performs testing to establish product performance. Typical testing activities undertaken by us include:

- Compilation of Qualification Test Plans & Reports

- Electrical Load Analysis (ELA) testing

- Electromagnetic Compatibility (EMC) & Interference (EMI) testing

- Flammability, Heat Release, Smoke Density & Toxicity testing

- Proof of concept tests

- RTCA DO-160 Environmental testing (temperature, altitude, vibration, shock etc.)

- Seat crashworthiness testing

- TEMPEST and Electromagnetic Security testing

- Transmitting Portable Electronic Device (T-PED) testing

Contact us

Rapid capabilities testing and modifications Contact Details

phoneDesign enquiries +44 1202 013778Supported aircraft

Airbus H145

The Airbus H145 helicopter is our aircraft of choice for HEMS operations. Find out more here.

Read moreBeechcraft King Air 200 series

We offer operational & maintenance expertise across the Beechcraft King Air 200 series of aircraft.

Read moreBeechcraft King Air 300 series

We offer availability and expertise across the BAE Hawker series of aircraft, including charter services, maintenance approval and capabilities and we have extensive management experience, having owned and operated BAE Hawker aircraft ourselves and for our clients.

Read moreBritten Norman BN2-T Islander

The Britten Norman Islander BN-2T is used within both a civilian and Special Mission context being able to accommodate various interior fitments from executive to up to three stretchers for Air Ambulance operations.

Read moreBombardier Challenger series

We offer availability and expertise across the Bombardier Challenger series of aircraft, including charter services, maintenance approval and capabilities and we have extensive management experience, having owned and operated Bombardier Challenger aircraft ourselves and for our clients.

Read moreBombardier Global series

We offer availability and expertise across the Bombardier Global series of aircraft, including charter services, maintenance approval and capabilities and we have extensive management experience, having owned and operated Global aircraft ourselves and for our clients.

Read moreLocations

Bournemouth International Airport (EGHH)

Our Bournemouth International Airport facility, a hangar and office facility of over 135,000 sq ft provides an extraordinary space which we aim to turn into one of Europe’s flagship business aviation facilities.

Read moreGroup Headquarters, 25 Templer Avenue, Farnborough.

25 Templer Avenue, Farnborough is home to our Group headquarters and is the nerve centre for the European Air division. With excellent access to the facilities at the airport.

Read more